Sample preparation

We investigate different kinds of ferroic materials and structures – may it be single crystals, thin films, multi-layer compounds or nanostructured metamaterials. For our envisaged optical or scanning probe experiments we often need to orient samples along specific crystallographic axes and achieve very low surface roughness values (< λ/10 for optical experiments and < 10 nm for force microscopy)

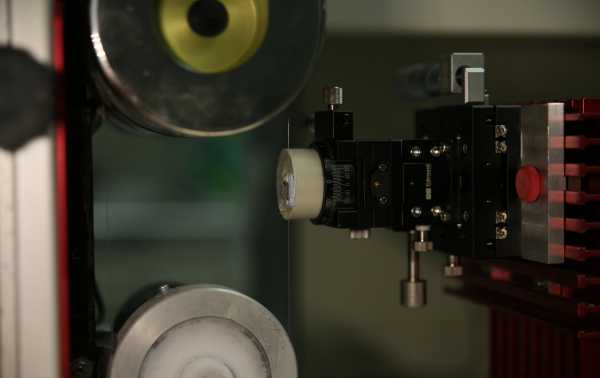

Orientation and cutting

We are able to orient our single crystalline samples can be oriented to any desired orientation (e.g. (001)-axis) by Laue back-scattering. Our self-built goniometer is compatible with both the Laue camera and the diamond-wire saw of our department allowing us to cut specimen slices (> 200 µm) along the determined crystallographic plane.

Lapping and polishing

Many investigated materials have high absorption coefficients, thus optical transmission experiments demand thin platelet samples with typical thickness < 100 μm. Thinning of samples (Ø 0.1 – 2 cm) with micrometer precision can be achieved by lapping, i.e. abrading the material with suspended hard particles (Al2O3, SiC, diamond). After that the surface is polished optically flat using either fine diamond particles or chemo-mechanical polishing agents. For water-sensitive samples we have the option to work with a glycol-diamond mixture.